Greyboard Gift Box Design and Applications: Practical Guide

In modern gift packaging, the greyboard gift box has become a preferred choice for jewelry, cosmetics, and high-end food products. Its dense fiber composition provides strength and stability while remaining lightweight, ensuring that products remain intact and visually appealing during display and transport.

Greyboard material is highly durable, capable of withstanding stacking and shipping pressures. Beyond gift packaging, it is widely used in display boxes, book covers, cosmetic sets, and export packaging due to its recyclability, cost-effectiveness, and sustainability.

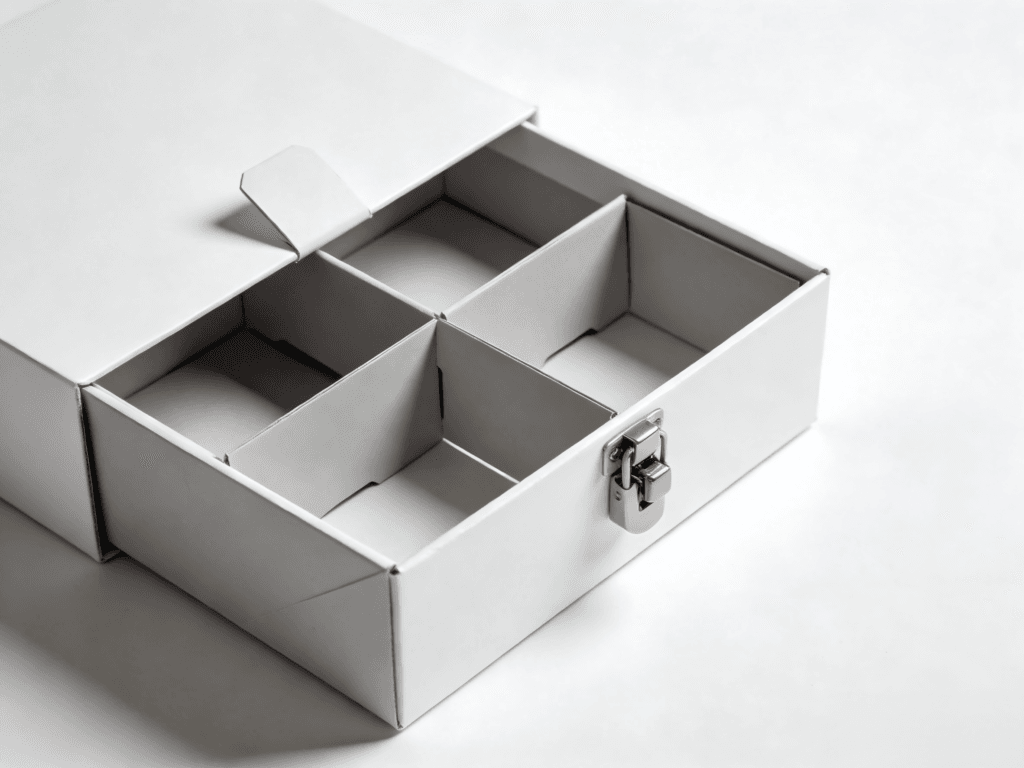

Creating a greyboard gift box involves careful selection of board thickness, structural design, surface finishing, and internal tray layout. These factors ensure that the packaging is both visually attractive and functionally stable, reducing product damage during shipping while enhancing customer satisfaction.

This guide covers material selection & thickness, structural design, surface finishing & processing, transportation & stacking, and cost & sustainability strategies, providing practical insights for designers and engineers.

For foundational knowledge, see [What Is Greyboard and How It’s Used in Packaging].

Table of Contents

- Material, Thickness & Structural Design

- Surface Finishing & Production Workflow

- Transportation, Stacking & Damage Prevention

- Cost Optimization & Sustainability

Material, Thickness & Structural Design

Selecting the proper thickness and density of greyboard is critical for a durable greyboard gift box. Jewelry boxes typically use 400–450 gsm for lightness and stability. Cosmetic sets require 450–500 gsm with multi-compartment trays to secure products. High-end gifts, such as ceramics or wine, demand 500–600 gsm for high load-bearing capacity.

| Application | Recommended Thickness (gsm) | Compressive Strength (N/mm²) | Tray Design | Features |

|---|---|---|---|---|

| Jewelry Box | 400–450 | ≥1.5 | Single compartment | Light and stable |

| Cosmetic Set | 450–500 | ≥1.6 | Multi-compartment tray | Organized separation |

| High-End Gifts (Ceramics/Wine) | 500–600 | ≥1.8 | Multi-layer tray | High load support |

| Display Boxes | 450–550 | ≥1.6 | Window + tray | Strong display effect |

| Export Packaging | 500–600 | ≥1.8 | Reinforced base + cushioning | Crush-resistant |

The process of creating a greyboard gift box is similar to making a handcrafted board box, but using greyboard provides higher load-bearing capacity and structural stability, making it especially suitable for high-value or fragile products. The standard workflow typically includes:

- Measuring product dimensions — Determine box size based on the product’s volume and weight.

- Selecting board thickness — Choose the appropriate gsm (e.g., 400–600 gsm) according to load requirements and aesthetic considerations.

- Cutting, folding, and gluing — Use die-cutting or automated cutting equipment to ensure clean edges, and employ professional adhesive techniques to secure the box structure.

- Adding trays or dividers — Design compartments or multi-layer inserts according to product shape for enhanced transport safety.

- Surface finishing — Apply matte or glossy lamination, UV printing, or foil stamping to enhance durability and visual appeal.

Industry authorities note that greyboard’s high rigidity and load-bearing capability make it ideal for rigid packaging structures, particularly for jewelry, cosmetics, and premium food gift boxes (see Greyboard Applications Guide for Export Packaging). Following this systematic workflow, designers can create gift boxes that are both aesthetically pleasing and practical, while significantly reducing shipping damage and increasing customer satisfaction.

Surface Finishing & Production Workflow

Surface treatments impact both the appearance and performance of a greyboard gift box. Matte lamination (12–15 μm) is scratch-resistant; glossy lamination enhances brightness but requires careful color control. Foil stamping adds a premium metallic effect, with temperature and pressure carefully managed to prevent warping. UV printing allows complex patterns, with proper curing to avoid marks during stacking.

Production workflow:

- Design confirmation: Determine thickness and box type

- Die-cut preparation: Ensure precise cutting

- Sample production: Test stackability, vibration resistance, and moisture protection

- Processing: Lamination, printing, foil stamping, or UV printing

- Tray/divider assembly: Tailored to product specifications

- Mass production preparation: Sample approval triggers large-scale manufacturing

This structured workflow demonstrates how a greyboard gift box moves from concept to production, providing clients confidence in reliability and durability. For detailed insights on greyboard manufacturing and its structural advantages, refer to Explore how greyboard enhances gift box durability.

Transportation, Stacking & Damage Prevention

Durable packaging is essential to protect products and maintain customer satisfaction. Proper transport design ensures that the load per box does not exceed 80% of its maximum compressive strength. Pallets can be stacked 4–5 layers high with cushioning between layers. Moisture-resistant bags or liners are recommended for long-distance shipping to prevent greyboard warping.

Even under heavy stacking or extended transport, greyboard gift boxes maintain integrity and visual appeal, reducing damage and enhancing the unboxing experience.

Additional transport strategies can be found in [Greyboard Packaging Applications Guide].

Cost Optimization & Sustainability

Cost drivers include material thickness, structural complexity, finishing processes, and transportation losses. Every 50 gsm increase in board thickness typically raises costs by 10–12%. Complex windows or multi-layer trays increase die-cutting and labor costs, while lamination or decorative finishes add further expense.

Optimization strategies include selecting the minimum thickness that meets load requirements, simplifying window designs, and reducing tray layers. For sustainability, using 100% recycled greyboard and uniform tray materials simplifies recycling. Water-based matte lamination reduces VOC emissions while maintaining durability.

These approaches ensure that greyboard gift boxes remain cost-effective, practical, and environmentally responsible.

Conclusion

This guide provides a practical blueprint for creating greyboard gift boxes, covering material selection, structural design, surface finishing, transport, and cost strategies. Using greyboard allows designers to craft packaging that is stable, visually appealing, eco-friendly, and suitable for high-value products.

For more application examples, see [Greyboard Packaging Applications Guide]; for foundational knowledge, refer to [What Is Greyboard and How It’s Used in Packaging].

Author Profile

-

HONGTUSCENERY is a professional manufacturer of composite paperboard,

providing sustainable and customized packaging solutions for global brands.

With nearly 20 years of industry experience, we focus on material performance,

structural strength, and green supply chain development.

Latest entries

Applications2026-02-17Greyboard Gift Box Design and Applications: Practical Guide

Applications2026-02-17Greyboard Gift Box Design and Applications: Practical Guide Applications2026-02-14Greyboard Applications Guide for Export Packaging

Applications2026-02-14Greyboard Applications Guide for Export Packaging Packaging Knowledge2026-02-10What Is Greyboard and How It’s Used in Packaging

Packaging Knowledge2026-02-10What Is Greyboard and How It’s Used in Packaging Packaging Knowledge2026-01-31Prevent Packaging Box Deformation: Material Matters

Packaging Knowledge2026-01-31Prevent Packaging Box Deformation: Material Matters