What Is Greyboard and How It’s Used in Packaging

(Pillar Guide for Packaging Professionals)

Walk into any retail store or warehouse and you’ll find rigid boxes, book covers, luxury cartons, and industrial packaging built on greyboard.

This recycled rigid paperboard forms the structural base of many packaging solutions that feel sturdy yet lightweight.

Many of these packaging structures rely on greyboard as an internal support material that provides strength, stability, and cost efficiency across supply chains.

Whether you are designing rigid packaging, bookbinding structures, gift boxes, or protective cartons, understanding greyboard specifications can directly influence product durability, cost control, and sustainability targets.

This in-depth guide explains:

- What greyboard is

- How greyboard is manufactured

- Technical properties and performance factors

- Common packaging applications

- How to select the right greyboard

- Sustainability and material trends

What Is Greyboard in Packaging?

Greyboard is a rigid recycled paperboard manufactured primarily from recovered paper fibers.

It is formed by compressing multiple layers of recycled pulp into dense sheets that deliver structural strength and dimensional stability.

Within the packaging industry, greyboard is valued for its core strength, not its surface appearance.

For this reason, it is commonly laminated with printed paper, coated paper, kraft paper, fabric, or specialty materials to create finished packaging structures.

Greyboard is typically made from recovered paper fibers and is part of the recycled paperboard category, widely used across global packaging industries.

Common industry terms for greyboard

Depending on region or application, greyboard may also be referred to as:

- rigid board

- recycled paperboard

- chipboard

- binder’s board

- carton base board

- rigid setup box board

Although visually simple, greyboard functions as a foundational structural layer for both premium packaging and industrial applications.

How Greyboard Is Manufactured

Greyboard production focuses on density, rigidity, and consistency rather than surface finish.

Manufacturing process overview

- Recovered paper collection

Post-consumer and post-industrial paper is sorted and processed. - Pulping and cleaning

Fibers are broken down and contaminants removed. - Layer formation

Multiple layers of recycled fibers are formed into thick sheets. - Compression and pressing

Sheets are compressed under high pressure to increase density. - Drying and cutting

Boards are dried, calendered, and cut into sheets or reels.

Because the material relies heavily on recycled fibers, greyboard manufacturing supports circular material systems and reduces dependence on virgin pulp.

Typical specification range

Greyboard is available in a wide range of thicknesses and grammages:

- 300gsm – 2000gsm+

- 0.5mm – 4mm thickness

- Custom density options available

This flexibility allows greyboard to be used in everything from lightweight cartons to heavy-duty rigid boxes.

Key Properties of Greyboard for Packaging

Greyboard is selected across industries because it balances structural performance, converting compatibility, and sustainability.

1. Structural rigidity

Greyboard provides strong compression resistance and shape retention.

This makes it ideal for rigid boxes, hardcover books, and protective packaging.

2. Excellent lamination base

The surface structure allows strong adhesion with:

- printed paper

- coated paper

- kraft liners

- specialty finishes

- fabric coverings

This makes greyboard a preferred base material for laminated rigid packaging.

3. Cost efficiency

Compared to solid bleached board (SBS), plastic, or wood-based structures, greyboard offers a cost-effective solution for large-scale packaging production.

4. Recyclability

Most greyboard is made from recycled fibers and can be recycled again after use.

This supports circular packaging systems and sustainability targets.

5. Custom density and thickness

Manufacturers can adjust:

- grammage

- density

- stiffness

- moisture resistance

to meet specific packaging requirements.

These characteristics make greyboard suitable for both premium and industrial packaging sectors.

Common Uses of Greyboard in Packaging

Greyboard is widely used wherever structural rigidity and dimensional stability are required.

Rigid gift boxes and luxury packaging

Laminated greyboard is commonly used for premium packaging such as:

- gift boxes

- cosmetic boxes

- jewelry packaging

- wine and spirits packaging

It provides structure while allowing decorative outer layers.

Cosmetics and consumer electronics packaging

Greyboard supports:

- protective inner structures

- rigid setup boxes

- presentation packaging

while maintaining a high-quality exterior finish.

Bookbinding and stationery

Greyboard is a core material for:

- hardcover books

- ring binders

- folders

- game boxes

Logistics and industrial packaging

Industrial uses include:

- corner protectors

- pallet edge boards

- inserts

- protective dividers

E-commerce packaging

Greyboard helps maintain packaging integrity during shipping and handling.

In most applications, greyboard functions as the internal structural layer, with outer materials providing branding and aesthetics.

How to Choose the Right Greyboard

Selecting the correct greyboard specification requires balancing structural needs, cost, and converting processes.

Key factors to consider

1. Thickness and grammage

Heavier products require thicker, denser board for structural support.

2. Compression strength

Important for stacking, shipping, and long-distance logistics.

3. Lamination method

Consider compatibility with paper lamination, foil stamping, or specialty finishes.

4. Moisture resistance

Critical for humid environments or long transit routes.

5. Sustainability targets

FSC certification or recycled-content requirements may apply.

Application-based selection

- Retail rigid packaging → higher density board

- Gift boxes → smooth lamination performance

- Industrial packaging → strength-to-cost balance

- E-commerce → weight and durability balance

Working closely with a packaging supplier helps ensure the board specification aligns with converting equipment, logistics conditions, and product protection needs.

Sustainability and Environmental Impact

Greyboard plays an important role in sustainable packaging systems.

Because it is produced largely from recycled paper fibers, it:

- reduces landfill waste

- lowers reliance on virgin pulp

- supports circular production

- has a lower carbon footprint than many plastic materials

Many manufacturers now offer:

- FSC-certified greyboard

- high recycled-content board

- low-emission production processes

For brands pursuing eco-friendly packaging strategies, greyboard remains one of the most practical structural materials available.

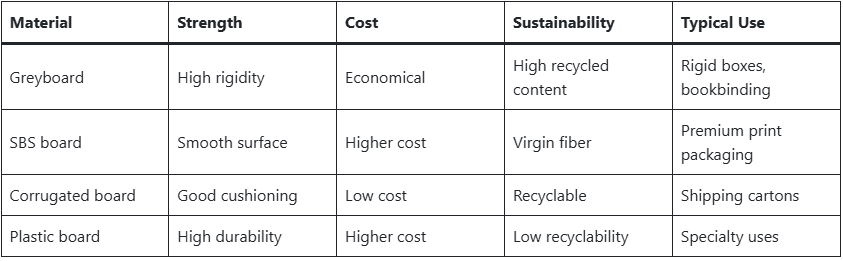

Greyboard vs Other Packaging Boards

Compared with alternative materials:

Greyboard occupies a key position between cost efficiency and structural performance.

Final Thoughts

Greyboard may not always be visible in finished packaging, but it is one of the most essential structural materials in the packaging supply chain.

From rigid retail boxes to protective shipping structures, it delivers strength, versatility, and sustainability.

Understanding greyboard specifications allows packaging professionals to:

- improve structural performance

- optimize costs

- support sustainability goals

- streamline production

If you are developing new packaging structures or refining existing ones, reviewing your greyboard selection is often a practical first step toward better performance and efficiency.

Author Profile

-

HONGTUSCENERY is a professional manufacturer of composite paperboard,

providing sustainable and customized packaging solutions for global brands.

With nearly 20 years of industry experience, we focus on material performance,

structural strength, and green supply chain development.

Latest entries

Applications2026-02-17Greyboard Gift Box Design and Applications: Practical Guide

Applications2026-02-17Greyboard Gift Box Design and Applications: Practical Guide Applications2026-02-14Greyboard Applications Guide for Export Packaging

Applications2026-02-14Greyboard Applications Guide for Export Packaging Packaging Knowledge2026-02-10What Is Greyboard and How It’s Used in Packaging

Packaging Knowledge2026-02-10What Is Greyboard and How It’s Used in Packaging Packaging Knowledge2026-01-31Prevent Packaging Box Deformation: Material Matters

Packaging Knowledge2026-01-31Prevent Packaging Box Deformation: Material Matters